Please sign my guestbook!

Sign My Guestbook  View My Guestbook

View My Guestbook

***DISCLAIMER***

(it's so pathetic that I have to do this; I HATE people that can't take responsibility for their own actions!)

This is ONLY documentation for my own project car. Should anyone decide to copy, emulate, or in any other way reproduce my ideas and/or methods, I bear NO RESPONSIBILITY for your actions. This is not a snap-tite model. There are no (quality) pre-fab kits out there that make it an easy 1-2-3 to do this conversion. This is custom work, and as such, is every bit as much art as it is science. Please ALWAYS think through what you're going to do before taking action, and PLEASE, Safety First!

Day 3 - Old Parts-Weights & Measures, Enter the SawZall, the Downsides of Not use the S15 Core Support

Old Part Weights:

- S13 240sx OEM Headlight assembly (with covers) x2 - 8.4 lbs

- S13 240sx OEM Hood - 40.0 lbs

- S13 240sx OEM Hood Hinges x2 - 1 lb

- S13 240sx OEM Fenders (w/front trim piece & sidemarker) x2 - 14.2 lbs

- S13 240sx OEM bumper (w/foam) - 20.6 lbs

- RPS13 240sx OEM radiator support brackets x2 - 1.3 lbs

- random hardware (OMG there was A LOT) - 2.2 lbs!

Total Weight of Old Parts: 112.6 lbs

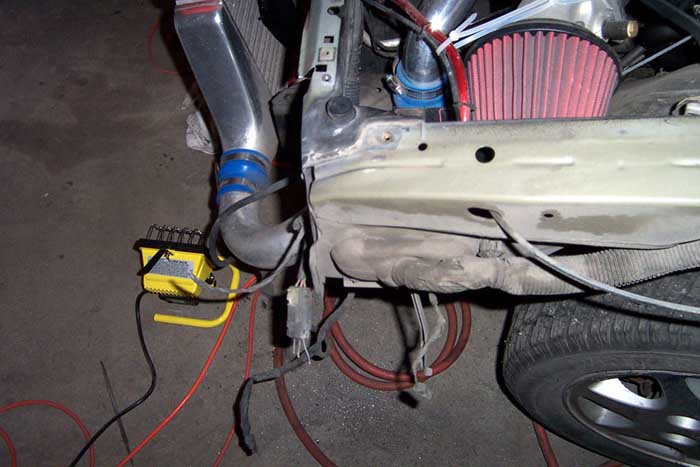

This is a quick overview pic of where I'm at currently. Had some setbacks, but nothing too major. The headlights don't quite line up, since i'm modifying the S13 radiator core support, rather than going with the $300 S15 core support that would need to be welded in. Several conversion I've seen use the existing support, but as you'll see in the following images, there are some definite drawbacks. Below you can see the light midway through being custom fitted. My deadblow hammer makes an amazingly accurate spacer for the light's mounting point :)

There have been many people saying that my fenders probably don't fit exactly right because my hood is mounted wrong. RIGHT. OK, so here is a pic of the hood and the hood hinge assembly... it really COULD NOT be more dead-on... look at the centering of the latch. The hood is currently the straightest, most correctly aligned part of the conversion, thus all other parts will go by the lines of the hood for fitment.

Before shot of the radiator core support: passenger's side

Mid-progress pic of the hole required for the S15 lights, more more modding is still required. I plan to weld on some small gauge steel stock when i've got the sizing right to add a little support and sheer strength to what I've removed. I was shocked to see how little strength the radiator core support adds to the car, it's VERY thing gauge metal (ie. you cut through it REALLY fast). There were 2 occurances (so far) when I got a little overzealous with the sawzall, but since this is all trial and error, I chalk it up to experience. Hopefully when I'm done, I can make a template for you guys who want to follow what I've done.... hey wait, I just realized that I should just drive around as-is and have a CAI! hehee :)

In this pic I was TRYING to illustrate how the upper-tack welded tab needs to be bent back slightly to compensate for the curvature of the S15 headlight, as it wraps around the corner. You can probably see better in the pic above than this one, sorry bout that folks.

As you can see, as of this entry, the lights sit just barely too far forward, almost exactly an inch too far forward, and probably 3/4 of an inch too high, it's bracket/spacer fabrication time!

Whoa baby, check out that gap... once the S13 core support is modded just a bit further, i'm confident the lights will line up, I just ran out of time for the night (I like to be courteous to my neighbors and NOT run the air compressor past about 8pm or so). Slowly things are coming together!

^ TOP